Imperial Bolts are important for securing metals in mechanical and engineering applications. Imperial bolts are known for their use in specific areas and industries. Let’s take a look at various types of imperial bolts, key features, and more.

Common Types of Imperial Nuts

Here are some common types of imperial nuts:

Imperial Hex Nut

An imperial hex nut has six sides that work with bolts and screws to secure things. It has a hexagonal design that gives a tight grip with wrenches. They are available in stainless steel, carbon steel, or brass and are used in the construction and automobile industries. Imperial hex nuts are used for heavy machinery, construction projects, and equipment installation where durability is important.

Imperial Hex Lock Nut

An imperial hex lock nut has a lock design that prevents it from loosening under vibrations and dynamic stresses. It has a nylon insert or a metal collar to improve its locking ability. It is available in a variety of grades and materials to meet varied load requirements. Imperial Hex lock nuts are used in automotive, industrial, and other applications that need a secure connection.

Imperial Flange Nuts

An imperial flange nut comes with an already added flange at the bottom that distributes the weight in a wider area and removes the need for a separate washer. It reduces the danger of damage to the fastened surfaces. Imperial flange nuts are used in the automotive and construction industries.

Acorn Cap Nut

An acorn cap nut is also referred to as a dome nut because it has a domed top that protects the exposed end of a bolt or screw. They are corrosion-resistant which gives protection from harm and decreases the chance of danger. Imperial acorn cap nuts are used to assemble furniture and vehicle interiors.

Imperial T-Nut

An imperial T nut is also referred to as a tee nut because they have a flange with prongs that dig into the material and secure the nut when a bolt is inserted. They allow for strong connections in wood or metal surfaces and give a strong grip on the textile. Imperial T nuts are used in woodworking and metalworking.

Imperial Square Nut

An imperial square nut has a four-sided shape that gives more surface area than an imperial hex nut and is simple to tighten and loosen. It will give a solid grip and reduce the chance of slipping while tightening. They are used for restoration work and furniture assembly.

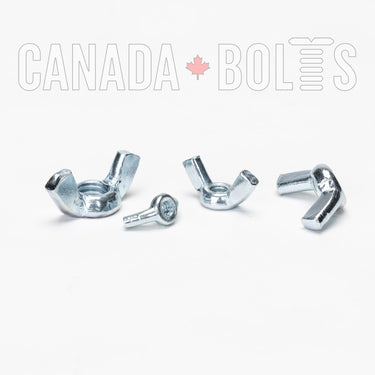

Imperial Wing Nut

An imperial wing nut has two wing-like bumps that will allow you to tighten and loosen them without using tools. They are used in industries that need regular assembly. They are available in stainless steel and zinc-plated steel. They are used to fix light and drum sets.

Imperial Coupling Nut

An imperial coupling nut is a long cylindrical nut that connects two threaded rods or bolts. It is used for increasing the length of a threaded connection. They are used to extend threaded connections in buildings, plumbing, and machinery.

Imperial Well Nut

An imperial well nut is a type of fastener that consists of a rubber outer body and an embedded metal nut. When it is tightened, it expands and provides a secure, vibration-resistant hold. They can be used in thin or soft materials in maritime, automotive, and lightweight structures that require a watertight seal.

Imperial Keps K Lock Nut

An imperial Keps K lock nut is referred to as a K-Lock nut and has a free-spinning washer to help prevent vibration-induced loosening. The built-in washer saves time and increases holding power. It gives a secure and tight lock and is used in automotive, electronics, and mechanical applications that require tightness under dynamic situations.

Advantages of Using Imperial Nuts

Imperial nuts have many advantages for tasks that demand accuracy and durability. Here are some advantages of using imperial nuts:

-

Strength and Reliability: Imperial nuts can withstand heavy loads and nuts you can choose imperial flange nuts to distribute loads.

-

Compatibility: They are available in a wide range of materials and types to fulfill various needs.

-

Ease of Use: Imperial bolts are simple to use because they have an easy system (inches).

Key Considerations for Selecting Imperial Bolts

When choosing imperial bolts for your project you should think of the following:

-

Material: Select a bolt material that matches the environmental conditions of your project.

-

Load requirements: Check if the nuts can withstand the load and pressures of the application.

-

Thread Type: To avoid wrong fittings, check if your nuts have matching threads.

-

Application Environment: If you have projects in high-vibration environments, you should use lock nuts to ensure safe connections.

Installation Tip for Imperial Nuts

Installing imperial nuts may look easy but here are some tips to install is safely and securely:

-

Select the right tools: Use wrenches or socket tools that match the nut size.

-

Apply Proper Torque: Do not overtighten to avoid damaging the nuts or materials.

-

Use Locking Nuts: Use hex lock nuts or other locking mechanisms to give stability in vibration-prone applications.

-

Check for Corrosion: If you are doing outdoor installations, check nuts regularly for rust or wear, and use corrosion-resistant materials as needed.

How to Maintain Imperial Nuts

Proper maintenance of imperial nuts can make sure that they are safe for a long time. Here is how to maintain them:

-

Regular Inspection: Check the nuts regularly to know if they are damaged. If you find it early, it will help you to prevent possible failures.

-

Lubrication Should Be Done Properly: Lubrication of bolts, especially those made of stainless steel, is to be done on the threads to avoid galling.

-

Checks for Tightening: Check if the nuts are properly tightened for vibrating situations. Sometimes, over-tightening can lead to stress fractures, while insufficient tension allows loosening.

-

Employ Coatings of Protection: In outdoor applications or under humid conditions, apply protective coatings or opt for nuts with a corrosion-resistant finish.

- Replace When Needed: Replace any nuts that show any visible signs of damage or have sustained an extremely high degree of stress.